Who we are

Established in 2005, Leather Working Group (LWG) began as a collaborative initiative among leading footwear, apparel, and upholstery brands, alongside leather manufacturers. Founding members include adidas, Clarks, Ikea, Nike, Marks & Spencer, New Balance, Timberland, PrimeAsia Leather Company and ISA TanTec

Since then, LWG has grown into the world’s largest stakeholder organisation dedicated to the leather industry, representing over 2,000 stakeholders across 60+ countries.

Our diverse multi-stakeholder group includes:

- Brands & Retailers

- Leather Manufacturers

- Traders (raw, part-processed, and finished materials)

- Suppliers (e.g., chemical producers, machinery suppliers)

- Industry Groups, NGOs & Associations

- Finished Product Manufacturers

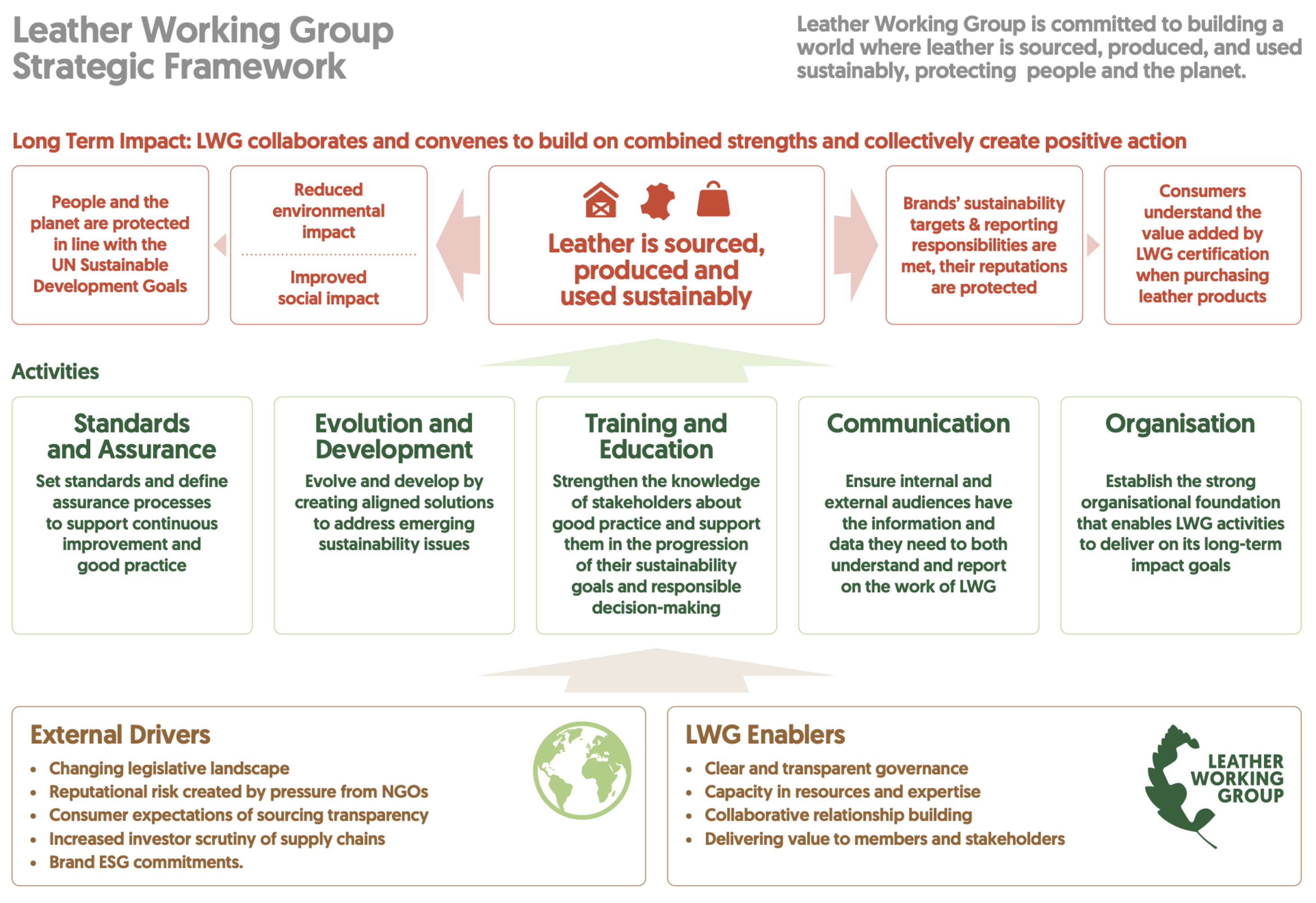

We are committed to delivering value to our stakeholders, with a mission to support and encourage the use of responsibly made leather as a sustainable material by inspiring, educating, and challenging those that produce and use leather. Through collaboration, convening, and standard setting, we are collectively creating a transparent leather value chain that achieves positive impacts aligned to the Sustainable Development Goals.

Our Mission

Leather Working Group (LWG) is a global non-profit, multi-stakeholder initiative committed to building a world where leather is sourced, produced, and used sustainably, protecting people and the planet.

Our Vision

Leather Working Group supports and encourages the use of responsibly made leather as a sustainable material by inspiring, educating, and challenging those that produce and use leather. Through collaboration, convening, and standard setting, we are collectively creating a transparent leather value chain that achieves positive impacts aligned to the Sustainable Development Goals.